First All Off-‘Road Shock Technology: Knowing your Options for Off-road Shocks

Off-road vehicles will see different amounts of aggressive terrain that must be handled with care and optimized equipment. There are different classes of shocks available and their differences can affect the ride quality, handling, and safety. Shocks designed for the off-road are made with high-end components to resist debris, premature failure, and corrosion.

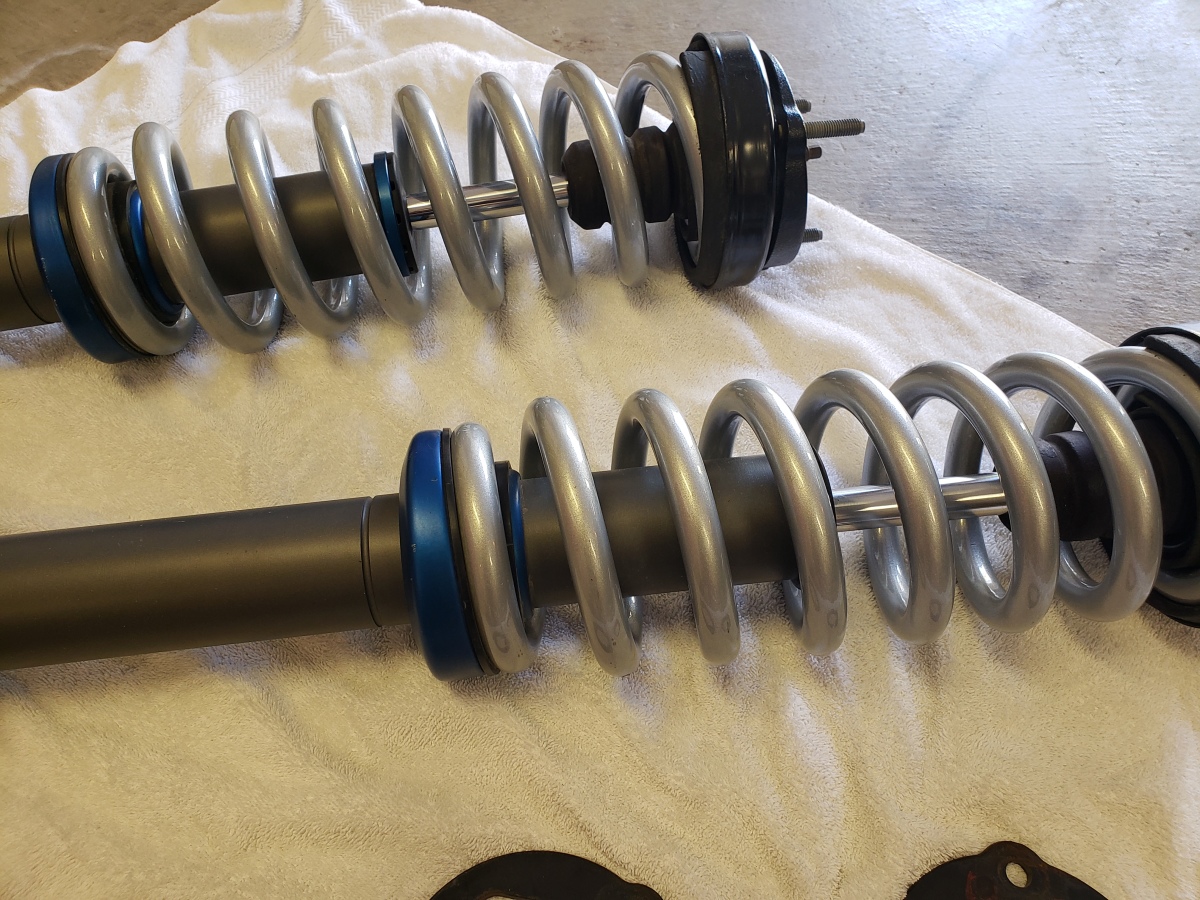

Modern off-road shocks provide incredible capabilities over factory shocks and struts. First Over All Off-Road Shock Technology or F-O-A is one of the leading suppliers of high-end off-road shocks. Its products can last 4 to 5 times as long, with the dampening ability being retained as the vehicle is put through aggressive terrain at moderate to high speeds. The company’s off-road shocks are intended for high eat, excessive debris protection, and consistent ride characteristics.

What are your Options?

The majority of offroad shock options available at F-O-A branches are a monotube design, with a nitrogen gas charge between 150-300 psi. These shocks offer better heat dissipation, bigger oil volume, more consistent damping, and more ride characteristics. But, this is not to say that all twin tube offroad shocks are not good. A lot of manufacturers make durable and amazing twin tube offroad schools with a purpose.

What Makes Off-Road Shocks Unique

The following are the major components of OE-replacement shocks that you can buy from F-O-A:

- Nitrogen gas. The gas is meant to keep consistent pressure on the shock oil. It helps prevent cavitation and aeration that can take place when shock oil boils in the low pressure areas of the piston during compression and rebound.

- Most aftermarket dampers use either a digressive or linear rate pistons. The most common piston offers a linear rate. A linear rate shock shows the rate in which the damper responds is directly relative to the force applied. On the other hand, a digressive piston can retain softer and compliant high-speed compression characteristics while having stiff low-speed compression characteristics.

- Bleed holes. These are the small holes on the piston not covered by the valves. F-O-A can purposely design these holes, which are meant to control the chatter in some off-road shocks when moving the piston through the fluid.

- Valve stack. The valve washer stack serves as a check valve that controls the high-pressure that gets to the low-pressure side. This is the reason the valving for compression is on the bottom of the piston instead of on top.